PART 4 OF 4 (Part 1, Part 2, Part 3)

by Ervin Somogyi

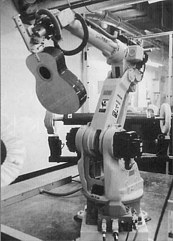

In the last installment of this series I wrote about what future changes can most be expected from factory-level guitar making. These, according to the industry’s own sources, have to do with advances in tooling, mechanization and technology, as well as in use of alternative materials in response to the dwindling and increasingly expensive supplies of traditional woods. These changes go hand in hand with the fact that quality of product is defined completely differently by commercial makers than by small-scale ones.

In the last installment of this series I wrote about what future changes can most be expected from factory-level guitar making. These, according to the industry’s own sources, have to do with advances in tooling, mechanization and technology, as well as in use of alternative materials in response to the dwindling and increasingly expensive supplies of traditional woods. These changes go hand in hand with the fact that quality of product is defined completely differently by commercial makers than by small-scale ones.

Quality, for the factory man, is identical with the degree of speed, efficiency and consistency attained in the making and assembly of identical things. This cannot be so for individual or small-scale makers, however, for obvious reasons: a lot of them work at vastly different levels of skill and creative talent and they may have different ideas of “best”, even though these ideas typically exist in reference to the objectives of good sound, playability, and user-friendly design. Frankly, hand-making can be so absurdly labor intensive that only adherence to the emotionally felt end of Getting Something Done Right would seem to justify it.  It’s been pointed out that comparing a handmade guitar to a factory made one is like comparing a painting to a toaster. While this sounds too affected and cutesy to be true at first hearing, it bears scrutiny. A painting is something which some individual somewhere took some time and effort to make, and it was likely made to please or satisfy some impulse. A painting might be good or bad or beautiful or charming or tacky, or personally meaningful. It may be original, interesting, spiritual, or well composed — or not. Some paintings can be amateurish, expressive, or static. Some speak to issues, emotions, ideals or themes. Some can be startling, even fascinating. And some paintings are timeless, significant and really great. A toaster, on the other hand, will do what it was designed and built to do, every time, or one fixes it or discards it. One does not normally think of a toaster as being a nice try, a masterpiece, original, happy, sad, thematic, childish, unintelligible, profound, clichéd, abstract, derivative or timelessly great. Toasters are not about being personally meaningful in any way. A handmaker is trying to make a useful tool for a musician, and to please himself in this effort. A factory’s main goal is to make mass produced goods to sell to a mass market. Qualitatively, these goals are about as different from one another as goals can be.

It’s been pointed out that comparing a handmade guitar to a factory made one is like comparing a painting to a toaster. While this sounds too affected and cutesy to be true at first hearing, it bears scrutiny. A painting is something which some individual somewhere took some time and effort to make, and it was likely made to please or satisfy some impulse. A painting might be good or bad or beautiful or charming or tacky, or personally meaningful. It may be original, interesting, spiritual, or well composed — or not. Some paintings can be amateurish, expressive, or static. Some speak to issues, emotions, ideals or themes. Some can be startling, even fascinating. And some paintings are timeless, significant and really great. A toaster, on the other hand, will do what it was designed and built to do, every time, or one fixes it or discards it. One does not normally think of a toaster as being a nice try, a masterpiece, original, happy, sad, thematic, childish, unintelligible, profound, clichéd, abstract, derivative or timelessly great. Toasters are not about being personally meaningful in any way. A handmaker is trying to make a useful tool for a musician, and to please himself in this effort. A factory’s main goal is to make mass produced goods to sell to a mass market. Qualitatively, these goals are about as different from one another as goals can be.

The quantitative differences are great, too. Small scale makers are competing for laughably infinitesimal niches of the market under conditions and with resources far different from those available to commercial producers. The small maker is ridiculously undercapitalized; he only rarely has an advertising budget, employees or staff; and his tooling is modest and often home-made. But, most importantly, inefficiency and expenditure of time are not his deadly enemies. In fact, to him, they’re his advantages. Whereas commercial producers have to assemble guitars quickly and efficiently, the small scale maker does not: his task is to refine and improve the product identified with him. Let me explain what I mean.

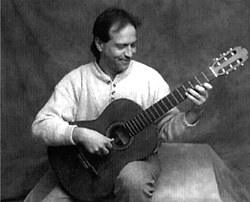

There now exists for the first time a body of steel string instrumentalists who bring wider, international sensibilities of musical voicings to their music. These musicians are also for the first time, in addition to being focused on the standard compositional and rhythmic aspects of their music, very much tuned in to the sounds and voicings they can get out of their boxes. Guitarists such as Ed Gerhard and Martin Simpson are for the first time playing steel string guitar music with pauses in it . While this is not a flashy enough development to have gotten much media attention it is, in fact, one of the most significant single developments in steel string guitar music in the past thirty years, and its threshold importance cannot be overstated. Pauses are what allow you to really hear a sound. An example of this new sensibility appears in the May-June 2000 issue of Fingerstyle Guitar in which Tim Sparks, a talented fingerpicker from North Carolina, says about a recently released recording that he “was trying to emulate the evocative sounds of crying, moaning and laughing that one hears in Klezmer violin or clarinet”. To talk about sound and expressiveness in this way is new, and it bespeaks a new need musicians have of their guitars. They will, at their own pace, seek out those makers and instruments from which they can get the warmth, dynamics, voicings and ergonomics that they want. Within my experience with my own clients these requests have included specific qualities of enhanced sustain, piano-like volume, responsivity and sensitivity to left-hand technique, brilliant and singing trebles, evenness of volume and responsiveness all the way up the neck, fidelity of intonation all the way up the fingerboard, necks comfortable to classically trained guitarists, guitars built for specific open tunings and/or designed around a player’s specific body size, superior recordability without need for equalization, great tonal expressiveness and depth, extremely specific action and intonation setups, ergonomic designs to get around a player’s physical limitations, and a wide range of dynamics and tonal colorations. The purpose of any and all of these qualities is to make someone’s music more satisfying, period. I think that such work — namely, really custom-working with a musician in a way that goes beyond merely mechanical things like fingerboard width, copying some features of the popular Brand X model, or beautifully intricate fingerboard inlays — will grow in importance for guitarmaking.

One of the forces fueling the quest for better sound is the fact that almost anyone can now record and burn their own CD albums. And many do. Since these individuals are expressing something out of themselves and largely for themselves, it’s perfectly understandable to think they’d sooner or later be on the lookout for a better guitar than they now have.

I think the demand for better guitars will have a general effect of encouraging refinement of design and more formal study of structure, acoustics, dynamics and playing technique. Small scale makers especially will want to learn the fine acoustical and ergonomic points of their craft, such as what effect ten thousandths of an inch less in the thickness of a top will have on bass response, how a bridge 2 mm higher will affect a note’s onset gradient, what difference the use of fir or redwood in braces might make, or what impact on sound the diameter of the soundhole has. Such minutiae are really — and always have been — the guts of lutherie work. As I mentioned in Part 2 of this series, classical guitar luthiers have long focused on the minutiae and subtleties of internal construction in the recognition that the relationship between structure and sound is what it’s all about. This is only beginning to be understood by steel string guitar makers, and the young ones are hungry for information. There will be increased dialogue between luthiers and musicians who are wanting guitars which are tonally ahead of them. This is not quite the same as a manufacturer agreeing to produce an individual musician’s signature-model guitar: sound doesn’t work like that, although commerce does. The process of wider learning has already begun with the establishment, in the past years, of several American lutherie schools; these are increasingly drawing students from abroad. Overseas students, especially from Japan, are also seeking and finding apprenticeship opportunities, most notably with members of the Northern California guitarmaking community. Northern California is not only becoming the Pacific Rim’s most active hotbed of lutherie activity but is also becoming a point of destination for both makers and students from all over this country.

In the end, whereas commercial makers will become more efficient at automation, mass production and marketing, custom makers will become more skilled, sophisticated, and experienced in doing the work on a small scale. The logic which drives commercial production is to eliminate delays, inefficiency and errors in production by eliminating the human factor as much as possible. The logic which informs custom making is to eliminate errors in production by increasing skill and mindfulness in the human element as much as possible. The fact that the imperatives which drive these groups are so opposite illustrates how little they have in common in spite of the fact that they are making products which look virtually identical.

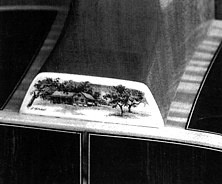

I expect to see other changes too. Since small scale makers are more able to spend time on individual projects than commercial operations can, I expect to see significant advances in artistic creativity and design as applied to ornamentation and custom work. Grit Laskin, Larry Robinson and I are spearheads in this movement at this time. The fact that such work is likely to be one-of-a-kinds or limited small editions, rather than the computer-operated designs produced in large quantities by commercial operations, makes them both more interesting and valuable, in my eyes. Since small scale makers are not in a position to capitalize their businesses to the point of using space-age materials, I expect their explorations into alternative materials to be largely limited to the use of real woods, real seashell, etc. And even if superplastics should become cheaply available, the rationale for a handmaker to use them escapes me.

I expect to see other changes too. Since small scale makers are more able to spend time on individual projects than commercial operations can, I expect to see significant advances in artistic creativity and design as applied to ornamentation and custom work. Grit Laskin, Larry Robinson and I are spearheads in this movement at this time. The fact that such work is likely to be one-of-a-kinds or limited small editions, rather than the computer-operated designs produced in large quantities by commercial operations, makes them both more interesting and valuable, in my eyes. Since small scale makers are not in a position to capitalize their businesses to the point of using space-age materials, I expect their explorations into alternative materials to be largely limited to the use of real woods, real seashell, etc. And even if superplastics should become cheaply available, the rationale for a handmaker to use them escapes me.

Carleen Hutchins has become famous in the violinmaking world for developing a family of violin instruments which vary in size in calculated and specific increments for the purpose of giving bowed instruments voices in all parts of the spectrum, from alto to tenor to baritone to contralto and everything in between. Banjos and mandolins of similarly premeditated sizes were made in the 1920s for the banjo and mandolin orchestras which were popular at the time. Guitarmakers have not yet, to my knowledge, entered the area of designing dedicated instruments around the specific problems of voicing — but as soon as a body of musicians arises whose music will be enriched by such, then small scale makers will be the first to make them.

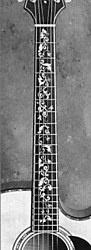

When this happens, I think it will likely start in regard to the fact that steel string guitars (unlike classicals) are commonly played in many open tunings: it’s an important and unique part of the steel string guitar’s life. The significance of this is that open tunings not only change the sensibility and voicing of a guitar as a function of their mode, key or harmony, but they also change the guitar’s energy dynamics (bright or mellow response, etc.) as a function of how much tension the strings put on the system. The player’s whole sound is dependent on how his guitar is tuned. And, if the player has a preferred tuning, then there’ll be a mode of construction that will make his guitar sound the best at that tuning and stringing. It makes sense to explore guitar design, soundboard thickness, refinements in bracing, optimal soundhole and bridge size, etc. with respect to the problems of a variety of specific stringings and tunings, and these will serve the needs of musicians who are, in effect, specialists. I think this will be one of lutherie’s growth areas in the future, and one in which commercial operations, which are best suited to standardization of design in the service of large scale production processes, are not likely to be able to compete effectively.

When this happens, I think it will likely start in regard to the fact that steel string guitars (unlike classicals) are commonly played in many open tunings: it’s an important and unique part of the steel string guitar’s life. The significance of this is that open tunings not only change the sensibility and voicing of a guitar as a function of their mode, key or harmony, but they also change the guitar’s energy dynamics (bright or mellow response, etc.) as a function of how much tension the strings put on the system. The player’s whole sound is dependent on how his guitar is tuned. And, if the player has a preferred tuning, then there’ll be a mode of construction that will make his guitar sound the best at that tuning and stringing. It makes sense to explore guitar design, soundboard thickness, refinements in bracing, optimal soundhole and bridge size, etc. with respect to the problems of a variety of specific stringings and tunings, and these will serve the needs of musicians who are, in effect, specialists. I think this will be one of lutherie’s growth areas in the future, and one in which commercial operations, which are best suited to standardization of design in the service of large scale production processes, are not likely to be able to compete effectively.

I should say a few, final, words about the growth and future of the guitar culture in general. When I was young the guitar was a nice instrument which people like Joan Baez, the Kinsgston Trio, Bola Sete, the Everly Brothers, Bob Dylan, Muddy Waters, Jose Feliciano, Elvis Presley, Peter, Paul and Mary, etc, etc. played on stage when Andres Segovia wasn’t in town, and about as often as not it was something that you bought a ticket to go hear.  But along with the growth of both lutherie and commercial guitarmaking an entire culture of guitar life has been created, not only in this country but internationally. This culture and ferment includes a vast body of students, teachers, players, pickers, pluckers, strummers, sliders and twangers; an equally vast body of instrumental recordings and published sheet music; the creation of a staggering corps of serious musicians and musical groups of all parts of the musical spectrum; the creation of music schools and lutherie schools, guitar departments of music conservatories, music societies, music camps and festivals, and workshops of many stripes; the appearance of annual contests, competitions, and prize awards for guitar events; the establishment of a huge network of agents, venues, tourings, bookings of gigs from beer-joints to concert hall appearances to stadium-filling extravaganzas, along with all the merchandising that goes along with these; the entering of MTV and other media involvement; the appearance of publications, newsletters, trade journals, magazines and internet websites for every kind of musical idiom that the guitar participates in (bluegrass, classical, rock, blues, folk, fusion, ethnic, experimental, etc.); commercial musical merchandising events and shows such as NAMM, vintage trade expos, and handmade guitar exhibitions; the creation of an international network of retailers, importers and exporters, experts, collectors, representatives and agents, middlemen, materials suppliers, shippers and insurers, and even museum curators knowledgeable about contemporary musical instruments; and, lastly, regional instrument makers’ organizations such as the Northern California Association of Luthiers, and professional shows such as the Guild of American Luthiers’ conventions, the Guitar Foundation of America’s conferences, and the Association of String Instrument Artisans’ symposia.

But along with the growth of both lutherie and commercial guitarmaking an entire culture of guitar life has been created, not only in this country but internationally. This culture and ferment includes a vast body of students, teachers, players, pickers, pluckers, strummers, sliders and twangers; an equally vast body of instrumental recordings and published sheet music; the creation of a staggering corps of serious musicians and musical groups of all parts of the musical spectrum; the creation of music schools and lutherie schools, guitar departments of music conservatories, music societies, music camps and festivals, and workshops of many stripes; the appearance of annual contests, competitions, and prize awards for guitar events; the establishment of a huge network of agents, venues, tourings, bookings of gigs from beer-joints to concert hall appearances to stadium-filling extravaganzas, along with all the merchandising that goes along with these; the entering of MTV and other media involvement; the appearance of publications, newsletters, trade journals, magazines and internet websites for every kind of musical idiom that the guitar participates in (bluegrass, classical, rock, blues, folk, fusion, ethnic, experimental, etc.); commercial musical merchandising events and shows such as NAMM, vintage trade expos, and handmade guitar exhibitions; the creation of an international network of retailers, importers and exporters, experts, collectors, representatives and agents, middlemen, materials suppliers, shippers and insurers, and even museum curators knowledgeable about contemporary musical instruments; and, lastly, regional instrument makers’ organizations such as the Northern California Association of Luthiers, and professional shows such as the Guild of American Luthiers’ conventions, the Guitar Foundation of America’s conferences, and the Association of String Instrument Artisans’ symposia.

As I said before, this is not bad for something that a bunch of skinny hippies had a hand in starting, and it’s taken on a life of its own. Parts of it are humble and informal, and parts of it are Big Business. And it doesn’t seem to be slowing down.

(reprinted from Fingerstyle Guitar, #43, 2001