A Surprising Insight About Drums and Guitar Tops

March, 2015

I received the following letter from one of my friends. It’s good enough to share with others. He wrote:

Dear Erv,

I had a wonderful ah-hah! Moment that startled me greatly. I was so enthralled at the time that I didn’t think to take pictures, so I hope my words will be enough to give you an idea.

We went with some friends to the new strip-mall built outside of town. I went scavenging around the back, being that kind of dude that is always looking for treasures left behind, like some cargo-cult islander or a stranger in a strange land. Near the little tin hut that houses cardboard, later to be crushed and bundled, was a strange box. I opened it to get a look at what was inside. Well, it was something I had never seen before: a brown plastic disposable keg, made like a big coke bottle, but much larger, about a 4 to 5 gallon capacity, and with a heavy-duty cap & a siphon to the bottom. In volume, it was about the same as a dreadnaught acoustic. It had a very thin skin, but the cap was industrially tough.

Of course I didn’t know anything about it, and was frustrated like a chimp because I could not unscrew the cap. I knew that if I took it back to my wife and friends, who were eating & schmoozing, they would not want me to keep it. I started to finger-drum it like a drum. It had the most amazing acoustic response. I just could not believe my ears & hands because it literally bounced with my fingers and made the loudest sound I ever got from any plastic bottle of any size. It was a wonderful drum. And because this strong drum was so wonderful I was determined to keep it.

So I got out my pocket knife and began to disassemble the cap guards so that it would be able to be all mine, minus the siphon. As I began to cut the locks on the cap, a tremendous amount of CO2 gas began leaking out… not for just a few seconds, but for a long long time. I was surprised at what great pressure this plastic bottle was under. I had to cut about 9 plastic safety locks, and even though I had done two-thirds of them, and the cap got loose, more gas kept on coming out. It was under a lot of pressure, and that kept the skin of the plastic alive and responsive.

As soon as all the gas came out and I removed the siphon, the keg was all as loose as an old man’s scrotum after 3 hours in a steam room. In more polite terms, as loose as a big balloon that had once been tight but had all the helium (or air) taken out. At that moment I was sad that I had lost my drum, but happy to just discard the now flaccid jug in the garbage where it now belonged.

All of this led me to fantasize that perhaps, in an analogous way, the braced system of a guitar gives the skin a similar “personality” — as if it were (in its own way) “pressurized”. Perhaps there is a better word, but for an example of the difference between responsive & non-responsive, I could not imagine anything better.

I’m thinking of you, and enjoying your books, of course. Someday I will do things. Progress is my most important product, elusive as it may be.

Your garbage-bandit friend, Alan

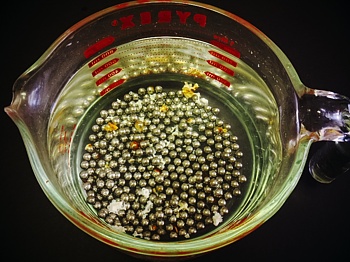

Titebond is only partially un-doable. This property of it impressed itself on me in an interesting and accidental way. I’d made a pencil holder a long time ago by pouring some Titebond into the bottom of a recycled plastic jar that had a rounded bottom edge and then dropping a bunch of ball bearings in for ballast — to ensure that it was heavy and stable enough to not tip over once I filled it with pencils and pens. The Titebond soon hardened and rendered the ball-bearing ballast permanent, and the jar held my pencils and pens nicely. Some years later I was able to afford a real pencil holder, so I transferred the pens and pencils and filled the old jar with hot water so as to melt the Titebond and reclaim the ball bearings. I thought it would take a few days of soaking for the Titebond to give way; the ball bearings were stainless steel and wouldn’t rust.

Titebond is only partially un-doable. This property of it impressed itself on me in an interesting and accidental way. I’d made a pencil holder a long time ago by pouring some Titebond into the bottom of a recycled plastic jar that had a rounded bottom edge and then dropping a bunch of ball bearings in for ballast — to ensure that it was heavy and stable enough to not tip over once I filled it with pencils and pens. The Titebond soon hardened and rendered the ball-bearing ballast permanent, and the jar held my pencils and pens nicely. Some years later I was able to afford a real pencil holder, so I transferred the pens and pencils and filled the old jar with hot water so as to melt the Titebond and reclaim the ball bearings. I thought it would take a few days of soaking for the Titebond to give way; the ball bearings were stainless steel and wouldn’t rust. As it turns out, it’s not only the composition of the glue that makes the problem for repairmen and restorers. It also has to do with how the adhesive achieves its results. In the case of the newer glues such as Titebond, these grab onto the materials they come into contact with by means of penetrative adhesion: they sink into wood fibers and grab hold. And once there, they want to stay. The upshot is that undoing such a joint usually results in some splintering, tearing, or pulling up of wood fibers, and thus leaving a rough surface that will itself need to be smoothed before any regluing can occur.

As it turns out, it’s not only the composition of the glue that makes the problem for repairmen and restorers. It also has to do with how the adhesive achieves its results. In the case of the newer glues such as Titebond, these grab onto the materials they come into contact with by means of penetrative adhesion: they sink into wood fibers and grab hold. And once there, they want to stay. The upshot is that undoing such a joint usually results in some splintering, tearing, or pulling up of wood fibers, and thus leaving a rough surface that will itself need to be smoothed before any regluing can occur. I cut my finger on my table saw, in a moment of carelessness. (Duh!) It of course happened at the end of the day, at the end of a run of cutting and slicing, and I’d allowed my mind to wander just a little bit. . .

I cut my finger on my table saw, in a moment of carelessness. (Duh!) It of course happened at the end of the day, at the end of a run of cutting and slicing, and I’d allowed my mind to wander just a little bit. . .